About Pete Lien & Sons

For over a half century, Pete Lien & Sons has provided construction materials for our communities to build a better world around us. The company’s commitment to customer service and product quality has helped it grow from its humble beginnings to today’s large scale, multi-state operation. Pete Lien employs a variety of advanced industrial equipment at various facilities, along with teams of employees to operate, inspect, and maintain this equipment.

Our Solution

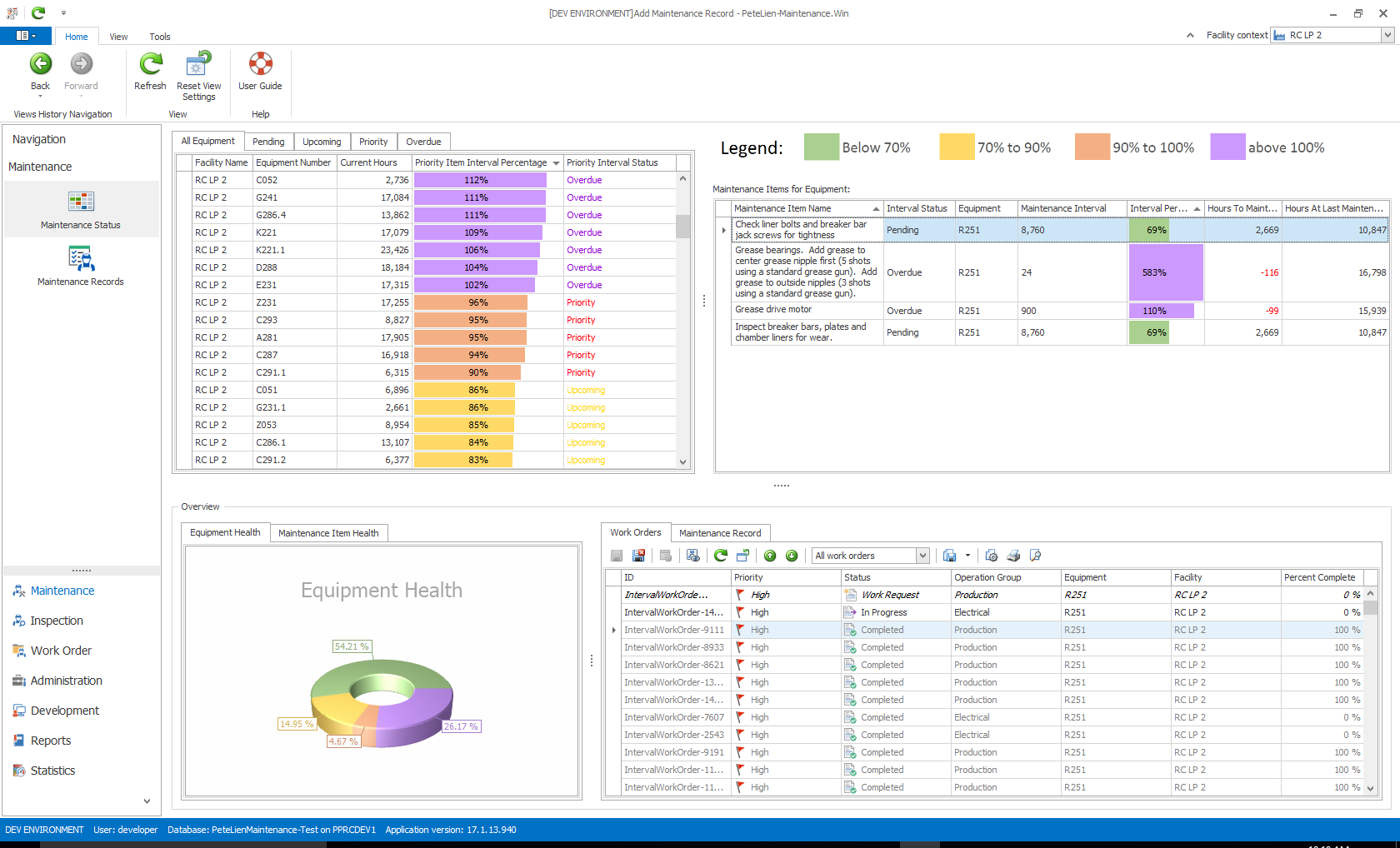

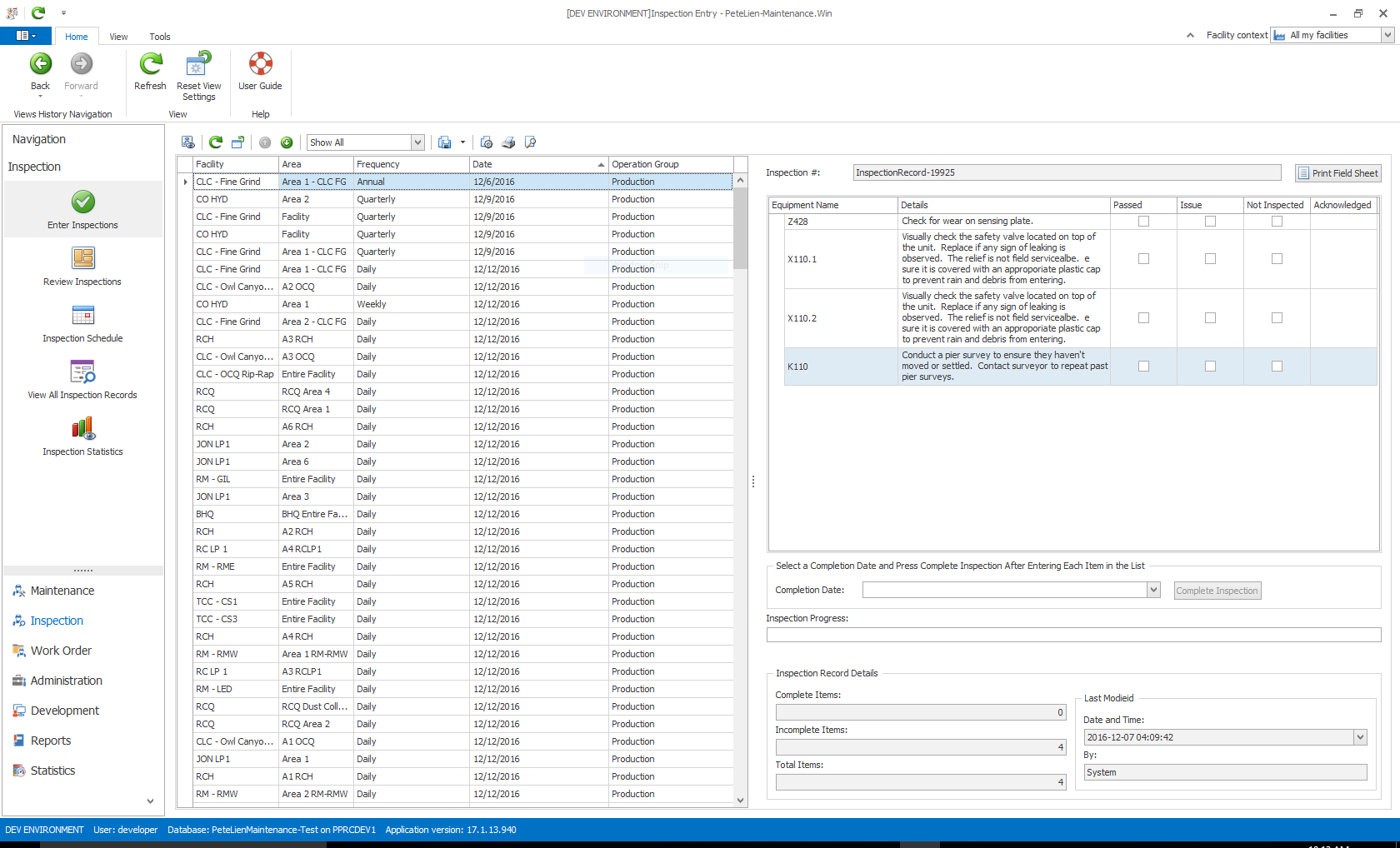

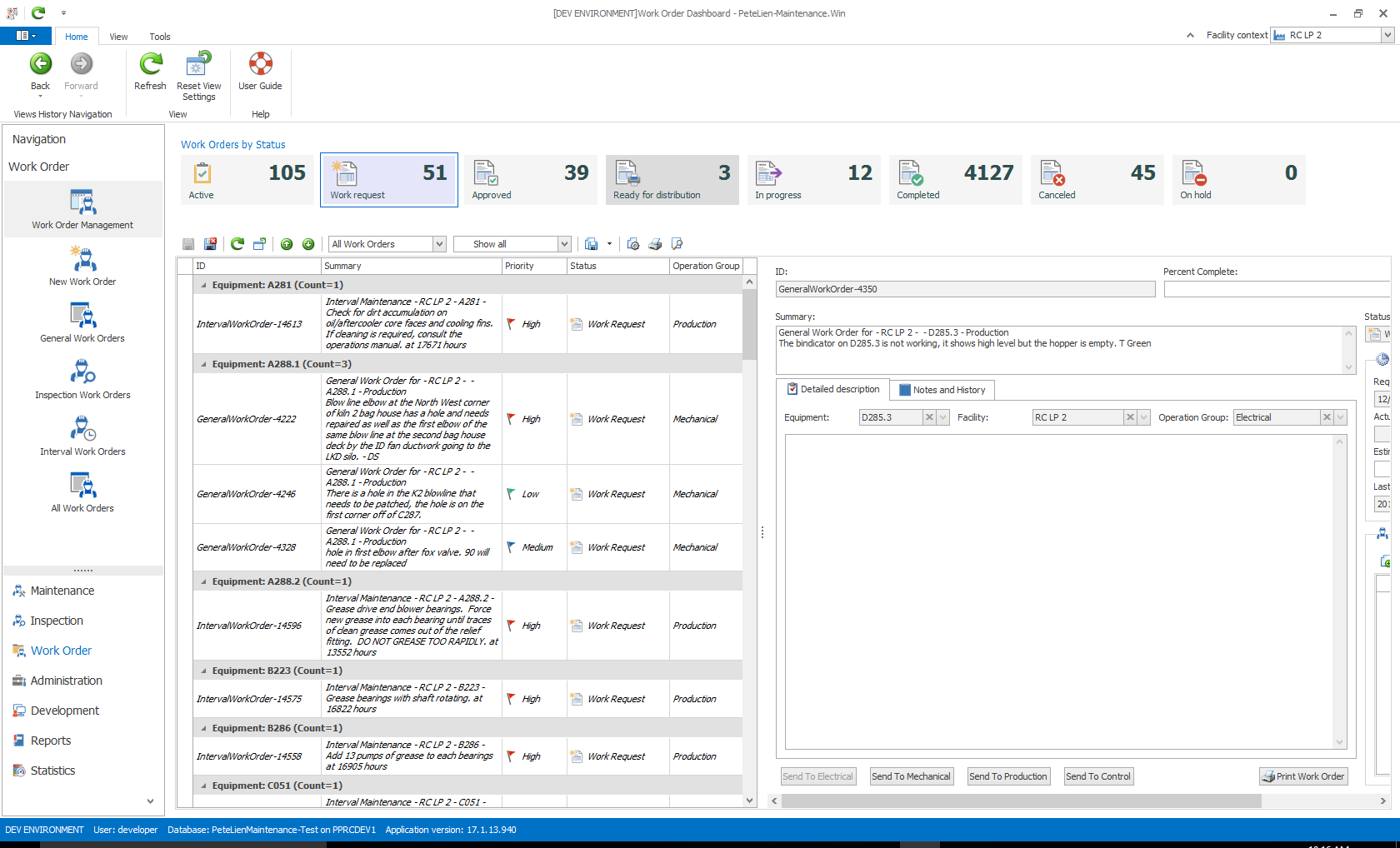

Pixel Pines worked with Pete Lien engineering and IT staff to design and develop a Preventive Maintenance system to manage inspections and generate work orders for failed inspection items and interval maintenance needs. Inspections and interval maintenance items are easily configured for equipment located at various facilities. The system generates over one thousand inspections and work orders on a monthly basis from data that is configured by Pete Lien employees.

Employees of Pete Lien & Sons serve in a variety of roles, and the Preventive Maintenance system adjusts based on the roles of the currently logged in user. This allows the user to only interact with functions that are relevant and authorized for their role. Certain employees only need to enter the results of inspections, while supervisors may need to review inspections and request or assign work orders.

The Preventive Maintenance System also provides a variety of methods for reporting on and viewing data as well as exporting data to a variety of formats including Microsoft Word and Excel.

Technical Details

Windows Desktop Application built with DevExpress eXpress Application Framework (XAF).

Microsoft SQL Server Databases supporting development, test, and production releases.

Terminal Services Deployment.

Featuring reporting and dashboarding supported by data processing and automation.